Our Services

Trafford Park – Case Study

Learn more about how our warehouse labelling supported a commercial client in Trafford Park

Racking Safety Services were referred to by a local storage equipment distributor to discuss possible improvements to a site in Trafford Park run by national and international business. This was for their Health Care division.

We visited and were shown around the site which was a typical operational site which had pallet racking that had been in situ for several years.

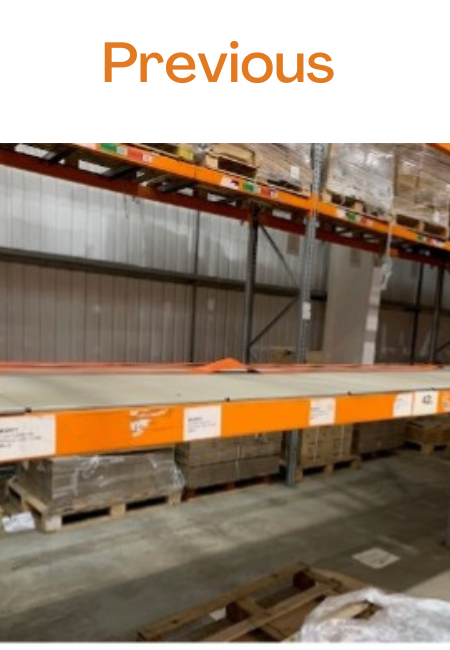

The site was poorly lit and the locations in the pallet racking and shelving were not clearly identified. There was further confusion by old paper product labels being placed on the beams too which added to operational confusion.

Our warehouse labelling solution

Please see a picture of a typical bay of how it once looked with a mixed bag of labels applied by the client previously.

How Racking Safety Services improved the warehouse beams.

The brief was to generally tidy the beams up and provide and expertly install high resolution barcode labels which would permit clarity of location and quick efficient scanning for a go live date in the future.

A number of options were discussed such as old label removal, and block out cover up labels. Our warehouse labelling solution was agreed to install cover up tape for the whole beam and then fix light, pastel coloured location labels professionally printed at the high resolution of (1200dpi).

Warehouse Beam Refresh For Aided Visibility

First part of the project was to cover up messy beams with orange tape without hinderance to the operation which needed to continue.

Light coloured picking (lime green) and bulk labels (light blue) were printed and fitted.

We then printed location labels from a location file provided and after creating a template which the client approved, Racking Safety Services systematically travelled through the warehouse aisle by aisle deploying our plan.

Warehouse Labelling Completed For Health & Safety Best Practice

Health and Safety is important in what we do and as this was to remain an operational site, even more so. We therefore taped each aisle in which we worked to keep safe the fitting team before moving into the next aisle and opening up the relabelled aisle back to the operation.

The go live date was met and the client was very happy with the project delivery saying the place looks much fresher and having saved him a lot of money on what now looks like “new beams”.

We have since asked to provide additional solutions such as end of aisle markers and bus stop signs each with high resolution printed barcodes for their marshal lanes and P&D stations.

Marshal lane bus stops with scan in / out barcodes

If you have any warehouse ID needs, Racking Safety Services would like to hear from you at info@rackingsafetyservices.co.uk or on 07376 726216

Learn more about our custom warehouse label products.

With our industry knowledge and experience, Racking Safety Solutions aim to match your warehouse with the best possible warehouse identification labels. Our warehouse label ranges from warehouse stickers to warehouse magnetic shelf label holders and inserts cards, and labels for freezer and chill warehouses; each option will be customised to your unique needs and requirements.

We excel in bespoke warehouse label solutions.

We match the correct print method and label substrate to your needs. This can range from professional UV printing, full colour printing to plastic labels, laser printing and thermal printing to custom metal warehouse labels. As specialists in warehouse labelling, planning and installation, our team will work with you to design the labelling areas from loading to picking bays and shelving. Maximising efficiency in your warehouse with clearly defined areas will reduce picking errors and time to pick during peak periods and help you create small margin gains with productivity.

You can contact our team here

How multilevel warehouse labels help you manage the location of racking within your warehouse.

Do you need:

• A labelling solution from truck-mounted readers to accurately scan barcodes.

• High-quality printing with complete definition

• Ease of racking level identification

• Organised colour co-ordination throughout the warehouse

• Improve scanning efficiency to your existing warehouse labelling with applications placed at eye level or placements on crossbeams.

At RSS we help you plan the warehouse labelling to your unique needs and arrange for a structured installation with minimal interruptions to your warehouse performance.

Warehouse Labelling Benefits

The RSS labelling service allows you to supply a premium solution to racking, shelving and floor location that is designed to ensure warehouse operatives are complying with your health and safety policy within their facility. It also allows for increases in productivity and fluid warehouse management with specialist barcode labelling/identification labelling. Bespoke to your needs and the racking install RSS provide labelling which is unique to your solution and the customers requirement.