Our Services

Warehouse Safety Netting

Warehouse safety netting is a fantastic solution that is suitable to warehouse environments and offers an innovative alternative to traditional methods of racking safety. Flexible, cost-effective and quick to fit, our warehouse safety netting is the perfect safety feature for your racking.

Netting is a modern option for the back of racks with a number of improvements and benefits over steel mesh. Helping to create a safer warehouse, netting reduces the risk of packaging and pallet spillage whilst still being aesthetically pleasing in a warehouse. We offer a number of different netting options, thicknesses and due to the nature of its flexibility, netting offers a long-term safety solution.

Our warehouse safety netting comes in the following thicknesses

(subject to client risk assessment):

- 2.3mm – preventing spillage of packages / boxes of 50kg off the pallet.

- 3mm – when the pallet is the risk and it sits on the racking beams only.

- 5mm – when the pallet is viewed as the risk but it sits on mesh or timber decks, or pedestrians are in close proximity.

Why work with Racking Safety Services for your warehouse safety netting

Our expert team advise and assist warehouse managers looking to work towards a health and safety best practice with safety netting solutions to help protect your inventory from damages and reduce the risk of potential injury to your team with displaced stock.

Professionally installed warehouse safety netting can help protect your workers, equipment, and inventory. For a reduction in the implications of stock movements during a pallet slip and the cost implications if your inventory is damaged in the process. Exploring warehouse safety netting solutions with our team will benefit your warehouse. Compared to steel safety netting, our mesh safety netting solution can be custom-made to your unique requirements; bespoke safety netting options include:

• The best possible mesh gauge to work for your project costs and to sit within your budget

• Customisation in the required strength of warehouse mesh

• Coloured netting to work with your warehouse’s colour-coded systems

• Bespoke mesh pocket sizes if needed.

Racking safety services are experts at custom warehouse safety netting solutions.

Our experienced team work with you to find resolutions to your health and safety best practice challenges in your warehouse with our unique custom safety netting products and advice.

As specialists in warehouse safety solutions, we will work with you to advise on many different anti-collapse netting options in various thicknesses that will protect your workers and your inventory.

We understand the challenges warehouse managers face when looking for safety resolutions in the warehouse to apply due diligence to protect your employees. Warehouse anti-collapse netting can be used as part of a safety system of works, aiding warehouse safety as a precaution against employee injury.

Call us today to speak to one of our experts and find the right safety netting solution for your warehouse.

Ready to discuss with our team?, you can contact us here

How warehouse safety netting reduces risk

Warehouses are full of hazards, and though safety plays an integral role in running most successful warehouses, there is one danger that often gets overlooked.

Pallet handling can lead to objects falling from a height, and it is a risk that could be significantly reduced with the installation of safety netting following a site assessment to reduce health and safety risks

Safety netting to create a warehouse barrier

Safety netting is an additional barrier that can be fitted to the vertical rear of warehouse racks to reduce the impact of pallet movements from the warehouse racking, creating a safer warehouse and reducing stock losses or damages. Warehouse safety netting is usually implemented as part of a safe system of works to reduce the impact of accidents.

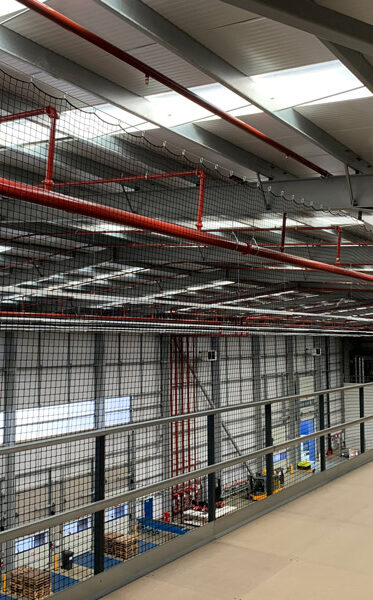

Safety netting for warehouse mezzanines

Safety netting can also be fitted on mezzanines to act as a barrier between the edge of the mezzanine and the ground below. This further protects damage from stock from falling and will act as a barrier for employees who may be working below or on the mezzanine floor.

Warehouse safety netting increases productivity.

Fortunately, when the worst does happen, and an incident occurs, whether a pallet gets caught or dislodged and shifted, installed warehouse safety netting on a mezzanine will reduce the impact of the hazard and allow your team to retrieve items quickly and easily.

Our solution to anti-collapse netting in the warehouse

You may be more familiar with warehouse steel wire mesh to protect against falling pallets in the warehouse; however, we offer a better, more flexible solution known as warehouse netting.

In comparison to steel mesh, safety netting is a far superior option for warehouses as:

● It can be fitted much more quickly

● It doesn’t get damaged when hit with a pallet, so that it will last longer, with added durability.

● It comes in multiple colours making it more visibly appealing

● It can be folded, which makes it easier and most cost-effective for delivery

Why choose warehouse safety netting?

- Warehouse safety netting can be fitted quicker than steel mesh and in some instances in half the time.

- Netting does not damage when hit with pallets in the same way as steel mesh does. It offers resistance but will move when force is applied, springing back to shape when the item is retracted. As a result of this the long term cost of ownership is less than steel.

- Safety Netting comes in multiple colour options and therefore cosmetically more aesthetically pleasing.

- The netting can be folded when being sent and as such more cost effective for delivery.

- Safety Netting does not require any special tools for installation.

- Multiple stand-off options