Our Services

Warehouse Line Marking

Warehouse line Marking is essential to ensuring that warehouses can function in a safe and functional manner. However, line marking is an ongoing problem with paint lifting or not sticking to the floor, which results in line marking failure in a very short period.

RSS offers a solution to fix this problem by using specialist line marking technology and floor preparation equipment to ensure that your line marking is durable and cost-effective.

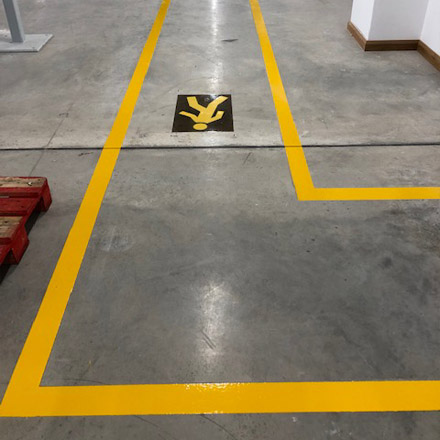

We offer 2 main areas of line marking, internal and external. Our internal line marking provides accurate systems for marking out warehouse floors or manufacturing facilities. Walkways, bay marking, secure/risk area marking etc are all available. External marking normally requires the use of thermo plastic being laid (similar to high ways line marking on tarmac roads) or spray paint for concrete floors.

Warehouses are a high-risk environment with many hazards that workers need to be made aware of to stay safe at all times.

RSS supports warehouse and operation managers looking to implement health and safety best practices following an assessment of potential risks, and advise on solutions as part of a safe system of works.

A simple yet highly effective way of doing this is through the use of warehouse line marking. Options include;

• Unprepared line marking as a temporary option

• Self-adhesive tape line marking

• Polycarbonate floor stencils

• For a longer-term warehouse line marking solution, shot-blasted marking will provide a durable result

Why use warehouse line marking?

Line marking has several different uses, significantly benefiting any warehouse that values safety and productivity.

With team safety being the top priority in any warehouse, the value of sufficient line marking cannot be overlooked.

The most important purpose that warehouse line marking serves is to clearly define where employees should walk whilst passing through the warehouse and highlight the most hazardous areas so that employees know where they should and should not be positioned during specific processes. It is a clear and constant reminder to workers should they forget safety protocol.

Warehouse line marking creates safety boundaries.

Line marking can also be used to create walkway boundaries by indicating to employees where stock should be kept (i.e. within the lines drawn around them) to ensure walkways are never obstructed such as a fire exit hatch and the importance of maintaining the area around the door clear.

Even hygiene stations can be line marked, encouraging sanitation levels to be upheld – something that has become increasingly important over the last couple of years

Create warehouse bays with line marking

Whatsmore, warehouse line marking allows you to set up marked bays in which stock can be arranged so that you can see exactly how much free space you have available. This can help you decide if there is a requirement for additional floor space and avoid the fatal error of a cramped and over-stocked warehouse.

This more organised environment will allow your employees to think and work more quickly and productively, which has endless further benefits for your facility.

Where are warehouse line markings found?

Line markings are often found, both internally and externally, in warehouses as a way of visually communicating:

Warehouse Walkways

To make it easy to identify pedestrian traffic and safe walking areas for workers and visitors.

Hazardous areas

To highlight emergency exits, automatic doors and heavy traffic areas for specific vehicles so they are not obstructed should your team need to evacuate the building.

Warehouse Floor layouts

To mark out production areas and one-way traffic to ensure maximum safety and productivity.

Warehouse Zones

To label areas with a high safety risk, such as loading areas and traffic zones.

Why talk to Racking Safety Services about warehouse line marking?

As experts in warehouse safety, we offer bespoke and professional solutions to all safety risks in the industry to reduce workplace accidents and give warehouse owners peace of mind.

Line marking is not a simple fix. When not done correctly, many warehouses can face issues, such as paint lifting or not sticking to the floor, resulting in line marking failure within a brief period.

Specialists in warehouse line marking planning

Our specialist line marking technology and floor preparation equipment ensures that your line marking stands the test of time. We guarantee durable, practical and cost-effective warehouse line marking that will satisfy the needs of your business.

Call to speak to one of our experts today about your warehouse line marking needs.

You can contact us here

.

Line Marking Variations

External Line Marking

tarmac or concrete line marking for outside area such as car parks, roads etc. Using wither thermo plastic solution or spray paint to mark the desired area.

Internal Line Marking

Shot blasted with 2 part epoxy is durable and typically lasts around 3 years (depending on truck movements etc). We can also offer a diamond floor shave system which is a more premium solution.

Floor Coating

This is a floor treatment service where epoxy is laid to the floor to increase the floors durability, makes it easy to clean and can eliminate cracks.