Our Services

External Line Marking – Case Study

Learn how we created additional car parking spaces

Racking Safety Systems were asked to attend a commercial site in Wellingborough to suggest a best practice solution for the conversion of a lorry yard into a staff car park.

A online retailer had recently taken over the site and were planning to increase the number of warehouse pickers and would need to consider where the extra people would park their cars and the current car park could only hold around 60 employee cars.

The warehouse site was attended and measurements taken to allow us to start mapping out how a layout to accommodate circa 200 car park bays could be shoe horned into the concrete finished lorry yard while maintaining a safe operation

Pictures of the old lorry yard at Wellingborough site. Old car park line marking and sleepers remanded on site which needed removing before the car park bays could be installed.

Available bay space improved for parking

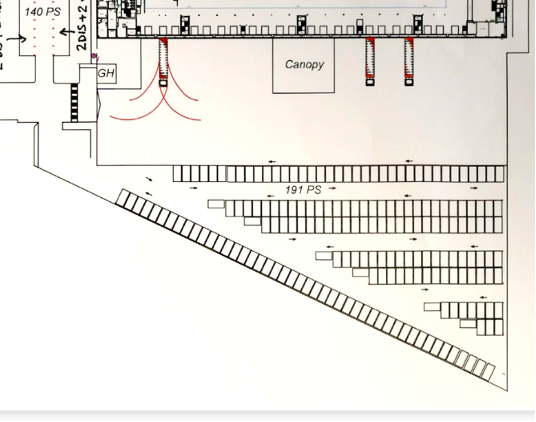

After reviewing the best use of space to achieve the additional parking for employees and further discussions with the client, we arrived with a layout which looked like the below which gave the end user 191 new car park bays. It also allowed enough room in the drive ways for cars to pass, reverse in and pull out of the bays

Our new external line marking plan

Proposed new car park plan at the commercial warehouse site in Wellingborough.

Costs were discussed and agreed together with start date and finish by date as they were due to start staff inductions for the 3 shift operations.

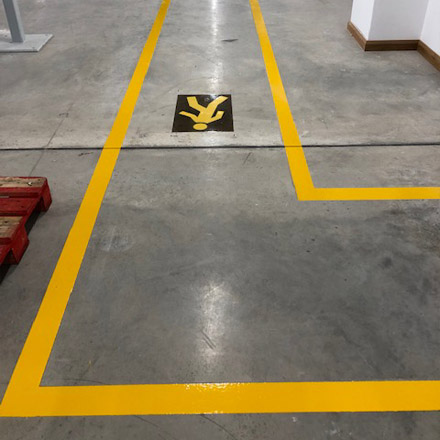

We arrived on site and promptly started to remove the unwanted yellow old lines with a heated lance. We then continued to mark out before seeking approval from on site General Manager. We then applied a primer and thermoplastic solution in the appropriate positions and the layout of the white car park started to emerge. White speed stencils, direction arrows were added along with zebra crossings and walkway.

Pictures of the new finished car park with old yellow lorry lines removed and new white arrow directional stencils, and car park bays installed.

The result was a happy client with a delivered car park brief in time for the interview and start of the new shift pattern.

If you have any warehouse line marking needs, Racking Safety Services would love to hear from you on 07376 726216 or at info@rackingsafetyservices.co.uk

Why talk to Racking Safety Services about warehouse line marking?

As experts in warehouse safety, we offer bespoke and professional solutions to all safety risks in the industry to reduce workplace accidents and give warehouse owners peace of mind.

Line marking is not a simple fix. When not done correctly, many warehouses can face issues, such as paint lifting or not sticking to the floor, resulting in line marking failure within a brief period.

Specialists in warehouse line marking planning

Our specialist line marking technology and floor preparation equipment ensures that your line marking stands the test of time. We guarantee durable, practical and cost-effective warehouse line marking that will satisfy the needs of your business.

Call to speak to one of our experts today about your warehouse line marking needs.

You can contact us here

.

Line Marking Variations

External Line Marking

Tarmac or concrete line marking for outside area such as car parks, roads etc. Using wither thermo plastic solution or spray paint to mark the desired area.

Internal Line Marking

Shot blasted with 2 part epoxy is durable and typically lasts around 3 years (depending on truck movements etc). We can also offer a diamond floor shave system which is a more premium solution.

Floor Coating

This is a floor treatment service where epoxy is laid to the floor to increase the floors durability, makes it easy to clean and can eliminate cracks.